Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

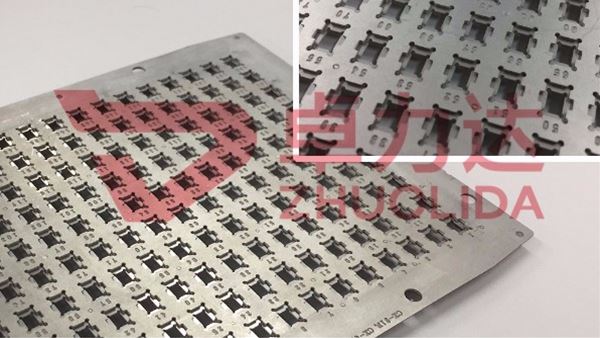

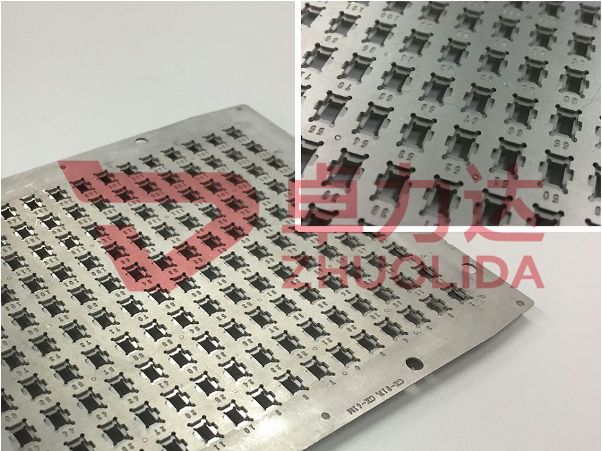

Vacuum diffusion welding is a process in which the joint is formed without liquid phase or only minimal transition phase. Its composition and structure are completely consistent with the matrix, no as-cast structure remains in the joint, and the original interface completely disappears. Therefore, the physical, chemical and mechanical properties of the original fund can be maintained without changing the properties of the material!

02

Vacuum diffusion welding is suitable for welding between metallic and non-metallic materials, especially for materials that are difficult to achieve by general welding methods, or are weldable but whose properties and structures are vulnerable to serious damage in the welding process. Such as dispersion - reinforced superalloy, fiber - reinforced boron - aluminum composite materials.

03

The vacuum diffusion welding is heated evenly and the welding parts are not deformed and residual stress is not generated. After the completion of the welding process, the workpiece will still maintain a high accuracy of the geometric size and shape, but also can be a variety of mechanical processing, such as wire cutting, laser cutting, bending, stamping and other processes.

04

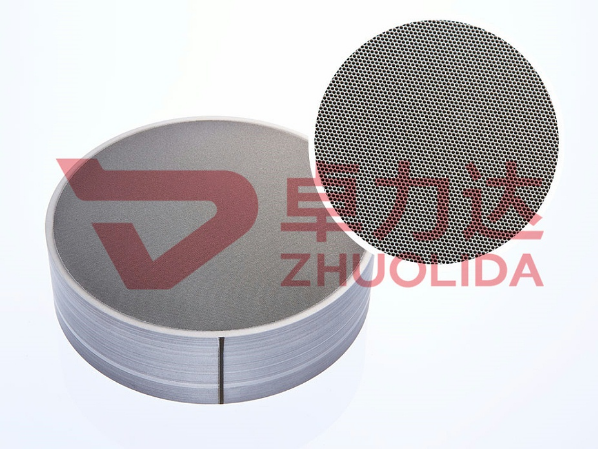

Vacuum diffusion welding can be used to weld different types of materials that vary greatly. Including dissimilar metals, metals and ceramics and other metallurgy completely insoluble materials.

ZhuoLiDa ZhuoLiDa with shenzhen, kunshan ZhuoLiDa, nantong ZhuoLiDa three production bases, including nantong ZhuoLiDa with nanjing university of aeronautics and astronautics, and Harbin industrial university is a vacuum diffusion welding technology and vacuum diffusion welding equipment r &d and manufacturing, set up a joint laboratory, common to do scientific research and technology research and development, now our precision etching products with vacuum diffusion welding technology widely military-industrial complex, medical, precision filter, mold, nuclear, semiconductor, equipment manufacturing industry automation, etc. We can provide free of charge vacuum diffusion welding processing solutions and information about the vacuum diffusion welding industry services.