Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

The inner wall of each channel of the microchannel plate is coated with a semiconductor material capable of emitting secondary electrons. When a certain voltage is applied to the microchannel plate, a uniform electric field is generated in each channel. This electric field is axial. Therefore, when the low-energy electrons (photons or electrons) entering the electric field collide with the wall, secondary electrons can be generated, and the secondary electrons are accelerated under the action of the axial electric field, so that the secondary electrons encountering the wall will produce more There are many new secondary electrons, so that for an incident particle, a lot of electrons will be generated at the output of the plate.

02

Micro-channel heat exchanger is a new type of heat exchanger. Compared with traditional heat exchangers, due to the reduced size of the internal heat exchanger plate flow path, the flow, evaporation and heat exchange mechanism have changed, which brings a series of advantages to the product, such as low material cost, Small size, light weight and high conversion efficiency. The introduction of micro-channel technology makes it possible to miniaturize highly integrated electronic equipment cooling and related cooling systems.

03

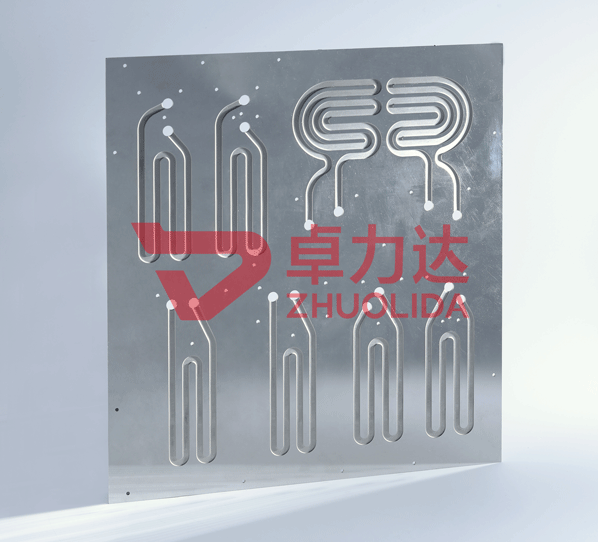

The microchannel plates are etched and formed once. On the same plate, the corrugation depth of the plates is the same, so that each contact point between the plates is perfectly connected. The guiding fluid alternately flows through the respective channels for heat exchange. , Small size, high heat exchange efficiency, save space.

04

The micro-channel plate is processed by chemical etching process. The spacing between plate flow channels can be adjusted, the depth of the flow channels is the same, the inner wall of the flow channels is smooth, and the welding surface has no scratches.

Compared with conventional heat exchangers, micro-channel plates not only have a small volume, a large heat transfer coefficient, high heat transfer efficiency, can meet higher energy efficiency standards, but also have excellent pressure resistance performance, which can be cooled by CO2 as a working medium, in line with environmental protection The requirements have caused widespread concern in foreign academic and industrial circles. If you are looking for a micro-channel plate etching manufacturer, please contact us. Zolida will be happy to help you!