Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

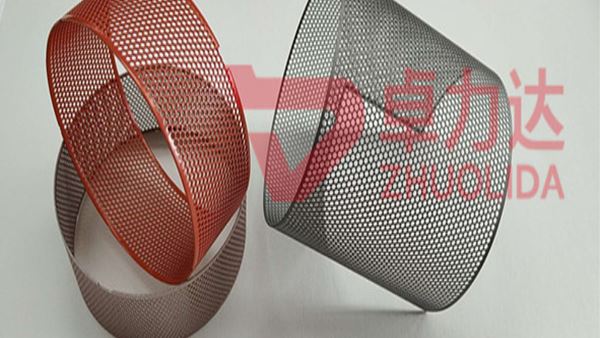

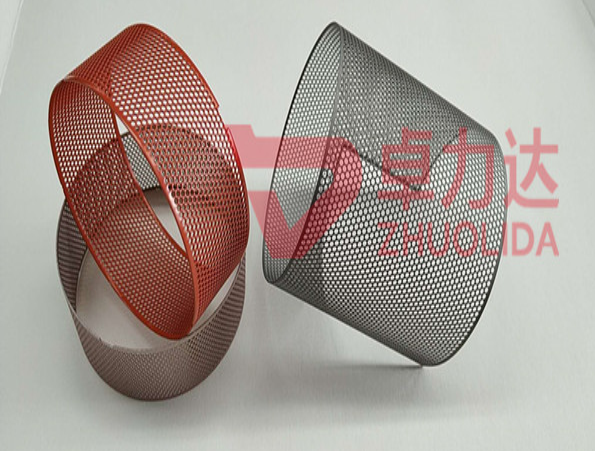

Vacuum cleaner filter filter precision is high, can cut off large particles of dust, so as to ensure the service life of the vacuum cleaner, greatly enhance the effect of ash removal.

02

Vacuum cleaner filter material high strength, good folding resistance, fatigue resistance, good permeability, moisture, can be reused and not easy to damage, which makes the filter cloth life can be extended.

03

Cleaning method of vacuum cleaner across the net:

1. Make sure the vacuum cleaner is in the state of power failure;

2. Open the dust bin and gently pull out the air inlet filter;

3. Rinse the air inlet filter with clean water, then place it in a cool and ventilated place to dry;

4. Take out the air filter from the back of the vacuum cleaner and clean the dust;

5. Finally, install the filter back to the original position.

04

Precautions for cleaning the filter of vacuum cleaner:

1. Do not use rubbing, rubbing and other methods when cleaning the filter to avoid damaging the filter;

2 vacuum cleaner filter can only dry, can not use other methods of ironing or blowing, baking, so it is easy to cause deformation of the filter;

3. Make sure the filter is installed in place before starting the vacuum cleaner, otherwise it will cause motor failure.

3. Make sure the filter is installed in place before starting the vacuum cleaner, otherwise it will cause motor failure.

The vacuum cleaner filter produced by zhuolida with chemical etching process has high precision and the aperture can reach 0.03mm.The pore diameter is uniform and uniform, the hole wall is hairless, and the flatness remains below 0.02.The thinner the material, the higher the precision control.We can process up to 0.02mm thickness of metal materials, up to 2mm thickness, can achieve mass production and processing, and the vacuum cleaner filter processing quality is stable, the batch is clear, the quality control system is strict.If you want to find a vacuum cleaner filter etching manufacturer, please contact us zhuolida, zhuolida staff will be dedicated to serve you!