Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product Introduction | |

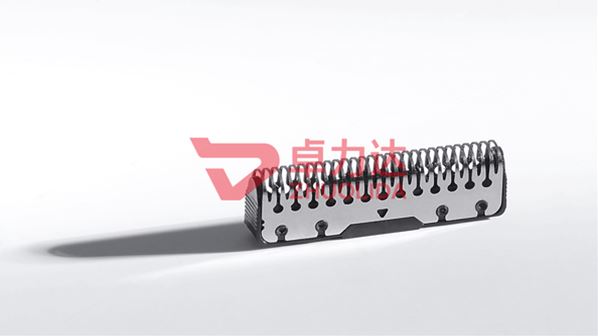

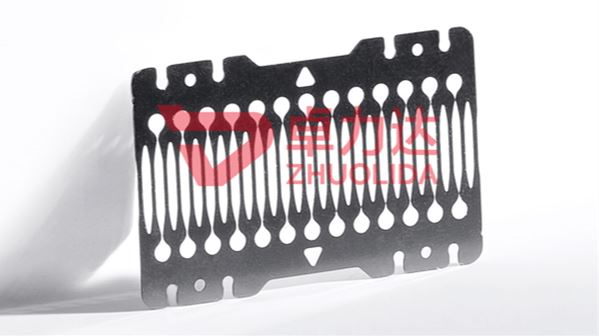

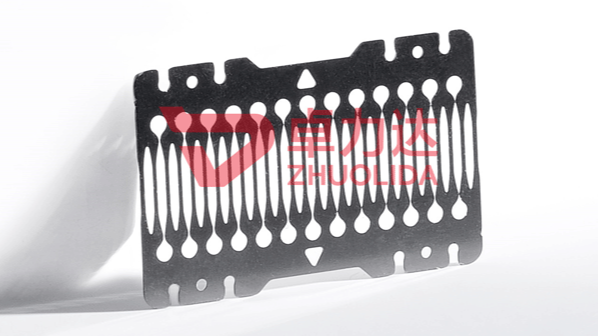

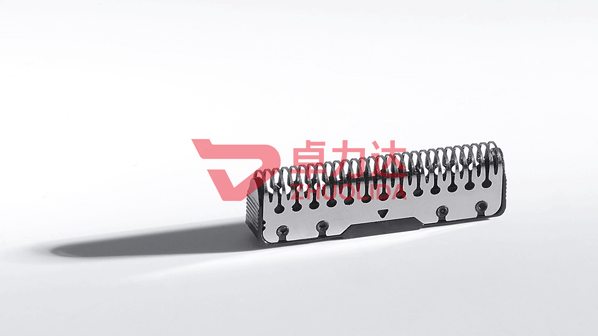

Product name: | Razor blade |

Product description: | Chemical etching razor blade various complex shape hairless, sharp cutting edge, accurate positioning hole. Razor blades are widely used in a variety of manual razors, hair scissors accessories, men's electric razors and so on. |

Samples provided: | Pay for sample making, sample within 3 days, 24 hours, can apply for free for special samples. Normally, we need to charge for samples. The main reason is to charge basic template fees and labor, water and electricity, and plant rent in the etching process. The etching process itself, due to its fast reaction time and relatively low cost, has saved a lot of costs for related design and manufacturing. As many as 100 kinds of new products need proofing every month, so the cost pressure is huge. In the spirit of mutual benefit, most of the customers in the communication also expressed understanding. |

Testing after sales: | Precision detection of secondary element and imaging instrument, 24-hour service hotline 0513-81601666. We are a precision etching factory and are responsible for all our products after sales. Whether it is service attitude, or product quality, communication about product design, sales quality of service, can be directly communicated. The factory has a superb quality control team, the rapid response mechanism, for customer complaints, within 24 hours to reply. Propose corrective measures within 48 hours and deliver qualified products within 3 days. |

Our strengths | |

1、Up to 2018, we have been engaged in the field of etching for 19 years. In 2015, the company invested in building a new industrial park in nantong, learned from the successful experience of shenzhen and kunshan branch, and committed to technical innovation, r&d, production and sales of razor net products in the middle and high-end market. Aspire to become China's etching industry hundred year enterprise! | |

2、The company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the company passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained a number of intellectual property patent certificates. Technology innovation and talent training are the driving force for enterprise development. Zolida has been focusing on technology research and development, and has cooperated with many universities, such as nanjing university of aeronautics and astronautics. It has set up laboratories, hired and trained high-tech talents, and is a benchmark enterprise in the etching industry. | |

3、The company is a member of PCMI, an organization of the world etching association, which can share information and equipment of the global etching industry. | |

4、The company has introduced a number of etching production lines, has a liquid medicine automatic addition system and regeneration system, the development of the company also pay attention to environmental protection, self-built large sewage treatment system, waste water reuse rate of more than 40%, is a rare in the metal etching industry to build a dedicated waterless treatment system of the manufacturer. The company aspires to become an environmental protection enterprise, green enterprise. | |

5、We can make razor blade thickness of 0.02mm, has been used in many brands of razors, according to the product, accuracy can reach +/-0.005mm. | |

6、With shenzhen zhuolida, kunshan zhuolida and nantong zhuolida three production bases, the comprehensive area of more than 40,000 square meters. Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions. The first floor of building 1, zhuolida, nantong is the electrophoresis workshop. The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the production capacity and precision requirements of various razor blade products. The fourth floor is the vacuum diffusion welding workshop. Building 2 is an electroplating industry. | |

01

We can produce razor blades in large quantities, up to 1000 square meters per day, for a small batch of diversified products, can also be semi-automated production, to save related operating costs, is the maximum for customers to save costs is our goal, become a high-end supplier of razor mesh.

02

The effect of shaving is mainly determined by the accuracy of the fit between the fixed blade and the moving blade. It requires that the spherical radian of the fixed blade and the movable blade should be matched properly, and there should be a pressure distance of about 1mm and a certain cutting Angle between the two blades. Pressure distance is too small, shaving is not sharp, and the feeling of plucking; If the pressure distance is too large, the power consumption and blade wear serious, but also will send out a sharp abnormal cry.

The processing capacity of razor blades is mainly evaluated by the company's automation equipment, and the more automated the process, the more efficient it is. The chemical etching production line owned by zhuolida company can be produced in large quantities, which can produce more than 100,000 kinds of razor blade products every day. If you need to make razor blade products, or you need to know the processing process and principle of razor blade, please contact us, we will serve you wholeheartedly!