Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product Introduction | |

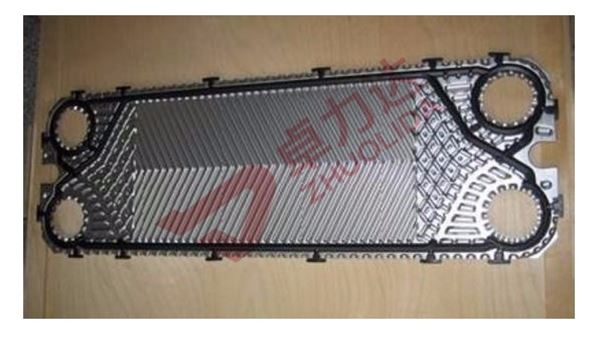

Product name: | Heat exchanger cold plate |

Product description: | Heat exchange cooling plate (Heat exchange cooling plate) is a metal plate manufactured by a precision etching process with a complex internal design for efficient heat dissipation. It flows through a cooling medium (such as water or air) in the flow channel to quickly transfer and dissipate the heat generated by the device. |

Product use: | Widely used in electronic equipment, lasers, new energy vehicles and other fields. |

After-sales service: | Precision detection of secondary element and imaging instrument, 24-hour service hotline 0513-81601666. We are a high-end and precise etching factory, and we are responsible for the after-sales of all our products. No matter the service attitude, or product quality, the communication about product design, the service quality of the salesman, can be communicated directly. Quick response mechanism, response to customer complaints, within 24 hours. Propose corrective measures within 48 hours and deliver good products within three days. |

Our strengths | |

1、Till 2025, we have been engaged in the field of etching for more than 20 years. In 2015, the company invested in building a new industrial park in nantong, learned from the successful experience of shenzhen and kunshan branch, and committed to technical innovation, r&d, production and sales of heat exchanger cold plate products in the middle and high-end market. | |

2、The group has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the group has passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained multiple property rights and patents. Zolida has been focusing on technology research and development, and a number of universities to carry out cooperation, laboratory and external employment and training of high-tech talents, is a benchmark enterprise in the etching industry. | |

3、The company is a member of PCMI, the world etching association, which shares new information and equipment in the global etching industry. | |

4、The company has introduced a number of etching production lines and vacuum diffusion welding equipment, has a liquid medicine automatic addition system and regeneration system, the development of the company also pay attention to environmental protection, self-built large sewage treatment system, waste water reuse rate of more than 40%, is a rare in the metal etching industry to build a dedicated waterless treatment system of the manufacturer. The company aspires to become an environmental protection enterprise, green enterprise. | |

5、The cold plates of heat exchangers were all produced in foreign countries before. Zolida introduced high-end technology, integrated etching and diffusion welding, and took the lead in the research in the field of micro-channel heat exchangers, which can provide the overall solution for customers. | |

01

Efficient heat dissipation: The use of high thermal conductivity materials (such as aluminum alloy, copper alloy), combined with precision etching process manufacturing complex runner design, to provide excellent heat dissipation performance.

02

Precision etching: Through etching technology to achieve high precision, complex internal flow structure, optimize heat exchange efficiency, ensure uniform heat dissipation.

03

Corrosion resistance: Material selection and surface treatment process make it have good corrosion resistance, suitable for a variety of harsh environments.

04

Customized design: The shape, size and layout of the runner can be customized according to the specific application requirements to meet the heat dissipation requirements of different devices.

If you need heat exchanger cold plate processing please contact us zhuolida company, zhuolida will be dedicated to serve you.