Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

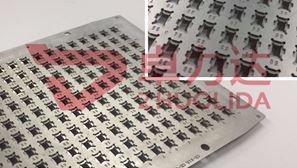

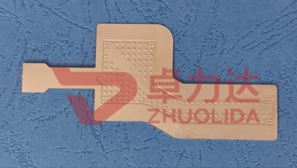

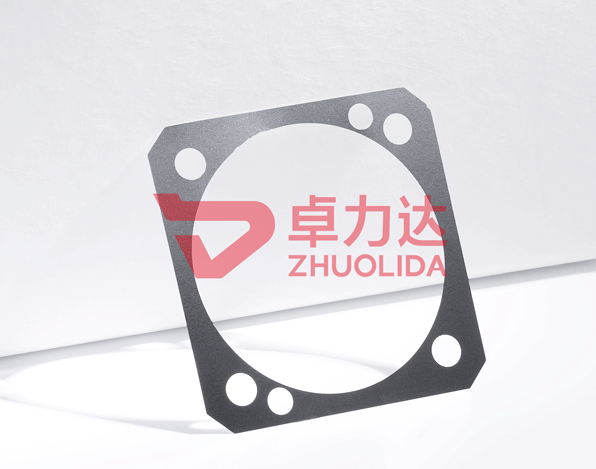

Traditional adjusting shims are generally formed by stamping with open abrasive tools, but the stamping process is relatively rough, the tolerance is large, and the accuracy is not high. For high-precision assembly requirements, the stamping process cannot meet such requirements. The adjustment pads produced by Zhuolida have high precision and are manufactured by chemical etching. The etching process solves the requirements of high-precision parts in industrial production , The small aperture can reach 0.1mm, and the hole wall is vertical, without any burrs.

02

All adjustment gasket products are subject to strict quality inspection before shipment to ensure that the products delivered to you are qualified products. If the customer raises a quality objection to our products, the company will make a handling opinion within 4 hours. If on-site resolution is needed, our company will send technical personnel and quality personnel to solve it. Those who do not solve the problem will not evacuate. Questions and results are archived for training and case studies.

03Nantong Zhuolida integrates multiple processes such as etching, laser and wire cutting. According to different requirements of customers' products, it can provide customers with corresponding processing solutions. Customers save costs.

The adjustment gaskets produced by our company can guarantee the precision, the precision can reach +/- 0.01mm, and the processing quality is stable, the batch is clear, and the quality control system is strict. Adjusting the gasket can meet the precise assembly requirements of different parts, and improve the quality and accuracy of the overall product. With precise, timely, convenient and environmentally friendly service concepts, the company has fast manufacturing, fast delivery systems and emergency service teams to serve every new and old customer.