Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

Molybdenum plate is very hard and very soft, resilient than tungsten molybdenum with high elastic modulus, tungsten, tantalum, only has the high melting point corrosion of molybdenum processing some of the common use of the products is molybdenum electrodes, application of vacuum furnace, nuclear, missiles and aircraft parts thickness from 00.090 inch to 3 inches, is listed as one of molybdenum plate molybdenum plate is widely used for mould and parts furnace construction, electronics and semiconductor components manufacturing organic silicon molybdenum plate is the use of silicon source Si2Cl6 and silicide conditions and its review some of the properties of the plate silicide molybdenum deposit first, such as 4 MoSi2, initial phase 6 metres ( After 10 minutes), and then the combined storage was carried out. After 30 minutes, a uniform layer of MoSi2 molybdenum silicide plate was formed. The weight of organosilicate plate dissolved by the anode increased by 0.2m sulfuric acid, which reduced the corrosion of sea sand of the layer thickness of MoSi2

02

Molybdenum is mainly used in iron and steel industry, most of them are industrial molybdenum oxide after the briquetting directly for steel or cast iron, a small number of melting into molybdenum iron molybdenum foil used for steelmaking of molybdenum content in low alloy steel after no more than 1%, but the consumption of molybdenum molybdenum is added to about 50% of the total consumption of stainless steel, will enhance the corrosion resistance of steel in molybdenum is added to iron, can improve the strength and wear resistance of iron containing 18% molybdenum nickel-based super alloy with high melting point small features such as low density and thermal expansion coefficient, Corrosion products used in the manufacture of molybdenum metal molybdenum in all kinds of high temperature components of aviation and space flight and rectifier tube transistor and other electronic devices in molybdenum oxide and molybdate is widely used in chemical and petroleum industry excellent catalyst molybdenum disulfide is a kind of important lubricant, used in the mechanical industry department in addition to this, molybdenum disulfide because of its special nature of the sulfur resistance, can under certain conditions the catalytic co hydrogenation preparing alcohols, is very promising C1 chemical catalysts

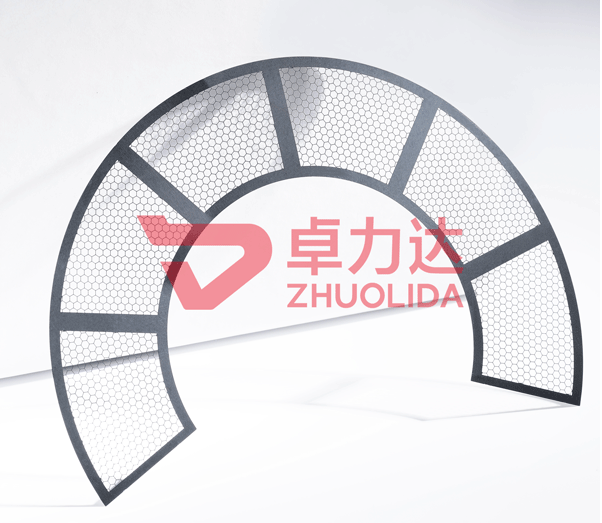

Corrosion of molybdenum processing products is widely used in daily life, everywhere thus arises at the historic moment of molybdenum processing factory is more and more but molybdenum plate is a brittle material and exceptionally hard, with stamping and wire-cutting processing, the corrosion of molybdenum products processing method is done by chemical etching process to nantong ZhuoLiDa with stable, high quality of molybdenum corrosion raw materials supply channels, precision etching process, powerful technical force and production equipment to ensure product quality