Product introduction |

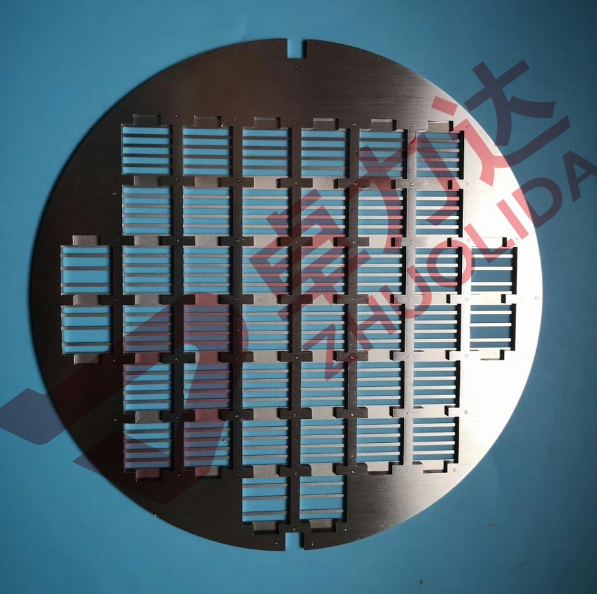

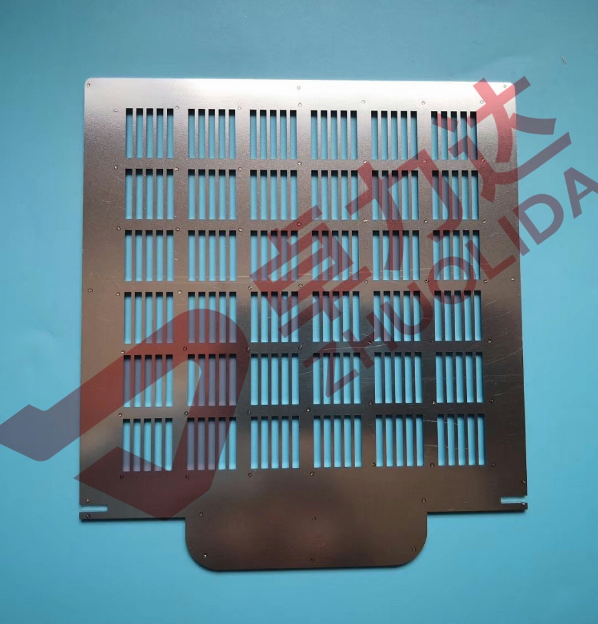

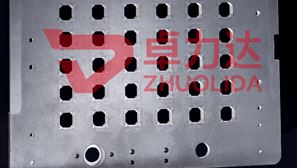

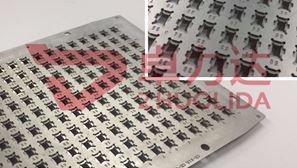

Product name: | Mask |

Product introduction: | We choose SUS304 H stainless steel material with high toughness. The mask made in this way not only has high accuracy, but also has a smooth surface. The product is not prone to bending and deformation. |

Product use: | The mask is used in electron beam evaporation, thermal evaporation, magnetron sputtering and other equipment to prepare solar cells, photodetectors, leds, lasers, transistors and other devices. |

technological process: | The workpiece to be welded is pre-fixed at the counterpoint -- into the furnace -- pressurized -- vacuumized -- heated -- pressure-protected -- cooled -- out of the oven -- inspected -- compound required shipment. |

Our advantages |

1、Up to 2018, we have been engaged in the field of etching for 19 years. In 2015, the company invested in building a new industrial park in nantong, learned from the successful experience of shenzhen and kunshan branch, and committed to technical innovation, r&d, production and sales of mask products in the middle and high-end market. Aspire to become China's etching industry hundred year enterprise! |

2、The company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the company passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained a number of intellectual property patent certificates. Technology innovation and talent training are the driving force for enterprise development. Zolida has been focusing on technology research and development, and has cooperated with many universities, such as nanjing university of aeronautics and astronautics. It has set up laboratories, hired and trained high-tech talents, and is a benchmark enterprise in the etching industry. |

3、The company is a member of PCMI, an organization of the world etching association, and is able to share new information and equipment for precision etching and mask in the industry. |

4、The company has introduced a number of etching production lines, has a liquid medicine automatic addition system and regeneration system, the development of the company also pay attention to environmental protection, self-built large sewage treatment system, waste water reuse rate of more than 40%, is a rare in the metal etching industry to build a dedicated waterless treatment system of the manufacturer. The company aspires to become an environmental protection enterprise, green enterprise. |

5、Various mask plates processed by chemical etching process and vacuum diffusion welding bonding process have extremely high precision, with the accuracy up to +/-0.01mm, which can be used for partial semi-corrosion of products. For thicker mask products, after etching, customers can also be helped to carry out vacuum diffusion welding bonding, and the whole process is delivered. |

6、With shenzhen zhuolida, kunshan zhuolida and nantong zhuolida three production bases, the comprehensive area of more than 40,000 square meters. Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions. The first floor of building 1, zhuolida, nantong is the electrophoresis workshop. The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the production capacity and the accuracy requirements of various mask products. The fourth floor is the vacuum diffusion welding workshop, which can help the group of customers to carry out vacuum diffusion welding bonding, and the whole process is delivered. Building 2 is an electroplating industry. |