Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product introduction | |

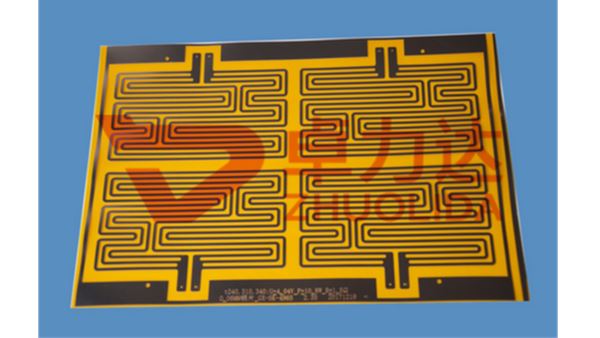

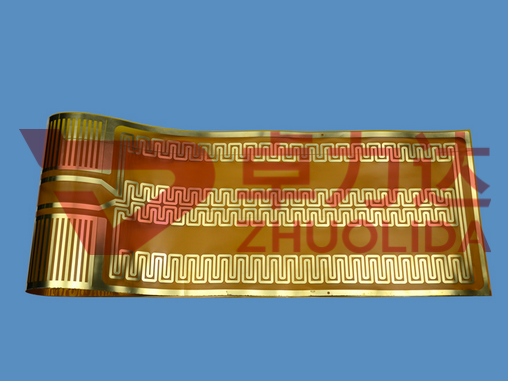

Product name: | Battery heater |

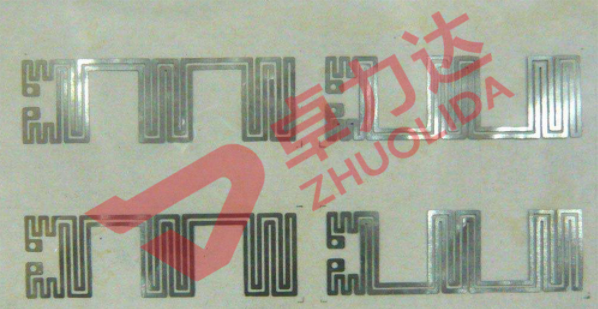

Product description: | Stainless steel or copper-nickel alloy is adopted to set the resistance through etching processing first, and then the PI film is pressed together by hot pressing to firmly bond to achieve insulation heating. |

Product usage: | It is mainly used for preheating in low temperature environment of automobile, communication equipment, medical equipment and new energy automobile battery. |

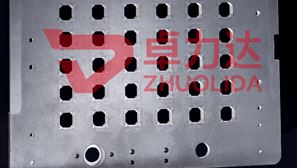

Processing method: | Material opening → cleaning plate → dry film or coating → drying → exposure → development → drying → etching → stripping → detection of packaging -- finished product shipment. |

Our strengths | |

1, 2019, we are working in the field of etching for 20 years, in 2015 the company spent in nantong new industrial park, draw lessons from the successful experience of shenzhen and kunshan branch, is committed to high-end market in battery heating products of technological innovation, research and development, production and sales.Aspires to be etched industry one hundred enterprises in China! | |

2. The company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the company has passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained multiple property rights and patents.Zolida has been focusing on technology research and development and has cooperated with many universities, such as China southern airlines and Shanghai jiaotong university. | |

3. As a member of PCMI, the world etching association, the company can share new information and equipment of the global etching industry. | |

4. Several etching production lines have been introduced, and the company has an automatic adding system and regeneration system for potions. While developing, the company also pays attention to environmental protection.The company aspires to become an environmental protection enterprise, green enterprise. | |

5. We can make the thickness of the battery heating sheet 0.02mm, and the precision can reach +/-0.002mm according to the product. | |

6. Shenzhen zhuolida, kunshan zhuolida and nantong zhuolida three production bases, with a comprehensive area of more than 40,000 square meters.Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions.The first floor of building 1, zhuolida, nantong is the electrophoresis workshop.The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the requirements of production capacity and precision of various products.The fourth floor is the vacuum diffusion welding workshop.Building 2 is an electroplating industry. | |

01

Research background: the battery heating pieces in the field of new energy electric vehicles, the power source of the currently used for lithium ion batteries, lithium ion battery has high density, no memory effect, long cycle life, no pollution, the advantages of light weight, small self-discharge, but greatly influenced by the low temperature environment on the lithium ion battery, will be serious influence on the performance of the battery charging, and greatly shorten the life of the battery.In addition, low temperature also poses challenges to the motor and air-conditioning systems.It can be said that low temperature is a major enemy of electric vehicles, without solving the above problems, electric vehicles will be difficult to promote in the northern region of low cold.

02

Advantages of metal battery heating sheet compared with traditional heating sheet:

1. Small space, light weight and thin thickness.

2. Excellent physical strength and softness make the heating element in good contact with the object being heated.

3. Flexible setting of size and shape can completely match the narrow space of the precision instrument.

4. The electrothermal film is designed in a planar way, and the surface power density can reach 10W/cm2, so the uniform heating property of the metal electrothermal film is more prominent, and the heating efficiency is further improved.

5. Small thermal inertia, flexible temperature control, temperature difference is only 2%.

6. As a protective layer, polyimide film has low saturated vapor pressure, low venting, and excellent resistance to chemical corrosion and radiation. Therefore, this product is suitable for vacuum environment, in contact with oil and most liquid chemicals.Such as: acid, alkaline, chemical solvent, new energy car battery electrolyte.

If you need to do battery heating sheet products, or you need to know the processing process and principle of battery heating sheet, please contact us, we will serve you wholeheartedly!