Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product introduction | |

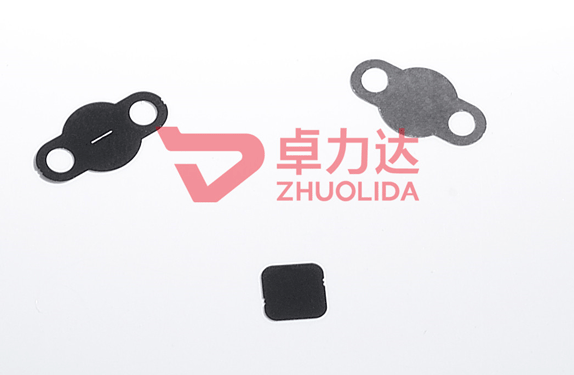

Product name: | 10 micron slit |

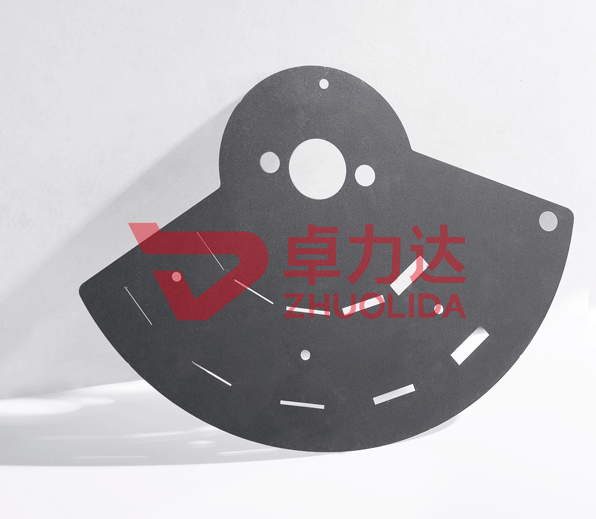

Product description: | Slit plate is usually a chemical etching process of metal sheet products, also known as transmittance plate or diaphragm plate or grating plate, etched slit plate gap smooth, flat without burr.Customers can adjust the width of the slit according to their actual needs and requirements. Our company can also help customers to blacken the surface of the slit products. After blackening, the transparency and shading effect of the slit is better. |

Product usage: | Mainly used in physical test, spectrum analyzer, electronic equipment, testing equipment. |

Processing method: | The main processing methods are divided into three types: linear cutting, laser processing and etching processing. Zhuolida will choose the corresponding processing methods according to customer product requirements. |

Our strengths | |

1. Up to 2018, we have been engaged in the field of etching for 19 years. In 2015, the company invested in the construction of a new industrial park in nantong.Aspire to become China's etching industry hundred year enterprise! | |

2. The company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the company has passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained multiple property rights and patents.Zolida has been focusing on technology research and development and has cooperated with many universities, such as China southern airlines and Shanghai jiaotong university. | |

3. As a member of PCMI, the world etching association, the company can share new information and equipment of the global etching industry. | |

4. Several etching production lines have been introduced, and the company has an automatic adding system and regeneration system for potions. While developing, the company also pays attention to environmental protection.The company aspires to become an environmental protection enterprise, green enterprise. | |

5. We can make slits with a gap of 10 microns and a thickness of 0.02mm. According to the product, the slit accuracy can reach +/-2 microns. | |

6. Shenzhen zhuolida, kunshan zhuolida and nantong zhuolida three production bases, with a comprehensive area of more than 40,000 square meters.Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions.The first floor of building 1, zhuolida, nantong is the electrophoresis workshop.The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the requirements of production capacity and precision of various products.The fourth floor is the vacuum diffusion welding workshop.Building 2 is an electroplating industry. | |

01

Spectroscope: Spectroscope is a scientific instrument that decompositions complex components of light into spectral lines. It is composed of prisms or diffraction gratings, etc. Spectroscope is used to measure the light reflected from the surface of an object.The seven colors in the sunlight are the visible part (visible light) that can be separated by the naked eye. However, if the sunlight is decomposed by the spectrometer and arranged according to the wavelength, visible light only occupies a very small range in the spectrum, and the rest are the spectrum that cannot be distinguished by the naked eye, such as infrared ray, microwave, ultraviolet ray, X-ray and so on.To determine what elements are contained in an article by capturing optical information with a spectrograph, developing it on a photographic plate, or displaying and analyzing it with a computerized display numerical instrument.This technology is widely used in the detection of air pollution, water pollution, food hygiene and metal industry.

02

Introduction and characteristics of slit: slit is mainly used in spectral instruments, etc. According to the working principle of modern spectral instruments, spectrometer can be divided into two categories: classical spectrometer and new spectrometer.Classical spectral instruments are instruments based on the principle of spatial dispersion.The new spectral instrument is an instrument based on modulation principle.Classical spectrometers are slit spectrometers. Modulation spectrometers are non-spatial spectrometers.According to the principle of dispersive component, spectrometer can be divided into: prism spectrometer, diffraction grating spectrometer and interference spectrometer.

03

Advantages of chemical etching of slits:

Chemical etching processing of narrow seam smooth without burr and notch, good straightness, chemical etching can also be made for a full plate, can also be a full plate for the black treatment of slot, after the treatment of a piece of the package for shipment, affordable, suitable for mass production.

04

Slit application:

1. Incident slit: the object point that forms the spectrometer imaging system under the irradiation of incident light.

2. Collimating element: causes the light emitted from the slit to become parallel.The collimating element may be a separate lens, reflector, or directly integrated on a dispersion element, such as a concave grating in a concave grating spectrometer.

3. Dispersion element: grating is usually used to disperse the optical signal into multiple beams in space according to the wavelength.

4. Focusing element: focusing the dispersive beam so that it forms a series of images of incident slits in the focal plane, where each image point corresponds to a specific wavelength.

5. Detector array: placed in the focal plane to measure the light intensity of each wavelength image point.The detector array can be a CCD array or other kinds of optical detector array.

We can process 5 micron slit, 10 micron slit, 15 micron slit, 20 micron slit, 25 micron slit, 30 micron slit, 35 micron slit, 40 micron slit, 50 micron slit and so on.The seam is smooth without burr and can also be blackened with various slits.If you need to do slit products, or you need to understand the slit processing process and principle, please contact us, we will serve you wholeheartedly!