Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

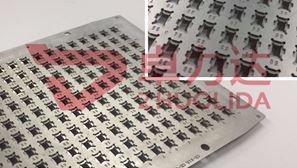

High precision etching: Manufactured by a precision etching process to ensure the accuracy and consistency of the channel.

02

High electron multiplication efficiency: The etching process optimizes the channel structure and improves the electron multiplication effect.

03

Long life: Durable materials and processes ensure long-term stability.

04

Miniaturization: Etching technology allows for smaller, more compact channel designs for miniaturization applications.

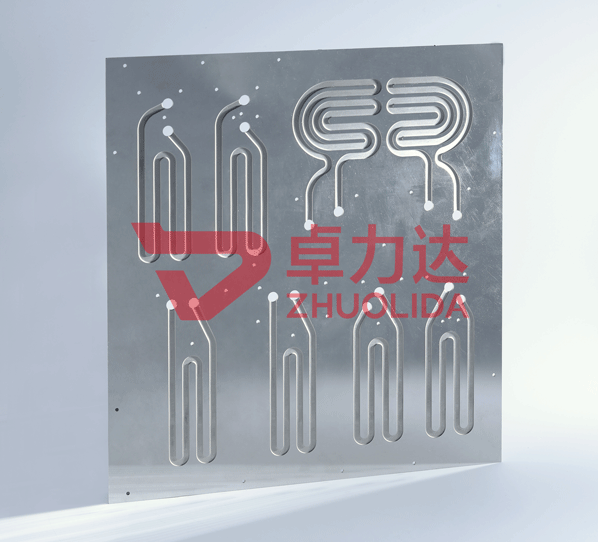

Compared with conventional heat exchangers, micro-channel plates not only have a small volume, a large heat transfer coefficient, high heat transfer efficiency, can meet higher energy efficiency standards, but also have excellent pressure resistance performance, which can be cooled by CO2 as a working medium, in line with environmental protection The requirements have caused widespread concern in foreign academic and industrial circles. If you are looking for a micro-channel plate etching manufacturer, please contact us. Zolida will be happy to help you!