Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product Introduction | |

Product name: | |

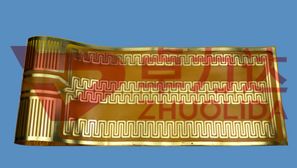

Product introduction: | It is made of imported / domestic stainless steel material and aluminum strip material. The layer tearing gasket product with the function of adjusting the gap can be peeled off layer by layer. |

product usage: | It is generally used to adjust the clearances of various motors and motors of electronic instruments, such as bearings, glass exposure machine motors, camera motors, projector motors, hydraulic equipment motors, lifting equipment motor bearing pads, and so on. |

Process flow: | Opening → cleaning sheet → coating assistant → kneading → calendering → lamination → molding → inspection packaging → finished product shipment. |

Our Advantage | |

1、As of 2018, we have been working in the field of etching for 19 years. In 2015, the company invested in a new industrial park in Nantong. Based on the successful experience of Shenzhen and Kunshan branches, we are committed to the technological innovation, research and development, production and sales of high-end market layer tear gasket products . Determined to become a century-old enterprise in China's etching industry! | |

2、The company has successively passed ISO9001: 2008 quality management certification and ISO14001: 2004 environmental management system. In 2016, it passed the ISO / TS 16949 certification for automotive industry, high-tech enterprise certification, and obtained a number of property rights patent certificates. Zhuolida has always focused on technology research and development, has a professional laboratory and has hired and trained high-tech talents. | |

3、The company is a member of the World Etching Association PCMI, and can share new information and equipment in the etching industry. | |

4、 At present, the manufacturing process standards for precision layer tearing gaskets are far from meeting the standards, especially the glued parts and the properties after peeling. Nantong Zhuolida has introduced 19 years of experience in high-precision industries such as aerospace and railcars and has introduced a variety of excellent quality , Preferable layer tear gasket products. | |

5、In the process of assembling parts, due to the total tolerance of each part, different gap ranges are caused, and the ability of layer tearing pads to be peeled off layer by layer can quickly and simply provide pads of different thicknesses to meet the need to make up for tolerances Time and process advantages. Layer tear gaskets also have economic advantages that can help customers reduce the need for a large inventory of solid gaskets. | |

6、It has three production bases in Shenzhen Zhuolida, Kunshan Zhuolida and Nantong Zhuolida, with a comprehensive area of more than 40,000 square meters. Among them, Nantong has established an industrial park, which involves etching, electroplating, anodizing, laser welding, and vacuum diffusion welding, etc., and can provide customers with integrated solutions. Among them, the first floor of Nantong Zhuolida Building 1 is an electrophoresis workshop; the second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the production capacity and precision of various products Requirements; the fourth floor is a vacuum diffusion welding workshop. Building No. 2 is the electroplating industry. | |

01

Directly adjust according to the measurement gap, immediately select the gap thickness, fast operation, and can be peeled directly without adding special tools. It is timely adjusted at the production site without affecting production and saving a lot of personnel time. It is also suitable for field work and easy to carry.

02

The layer tearing gasket has a wide range of applications, can be resistant to high temperature, high pressure and can be used under low temperature or vacuum. Strong application compensation. It has stable sealing performance, high reliability, and good sealing performance at the stations with high temperature and high pressure fluctuations.

03

It is made from the surface adhesive layer and interlayer resin adhesive of precision metal foil or composite film. The foil can be aluminum, stainless steel, copper and other metals. The thickness of the gasket can be from 0.01-1.0. The adhesive layer is made by heat and pressure, and the resin decreases to an almost undetectable level after hardening. When the temperature is higher than 150 degrees Celsius, the effect of the adhesive will be poor, but the overall thickness will not be affected. Even if the temperature rises to 220 degrees Celsius, it will not affect the performance of the gasket.

04

If you need a certain thickness, you can tear off the unnecessary layers until the required thickness, without any tools, it is very easy to adjust. We use precision metal foil layers to bond together with a certain rigidity to ensure that the gasket can withstand shearing and machining.

The layer tear gasket produced by our company can guarantee the precision, the precision can reach +/- 0.01mm, and the processing quality is stable, the batch is clear, and the quality control system is strict. It can meet the precise assembly requirements of different parts and improve the quality and accuracy of the overall product.