Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product introduction | |

Product name: | Anodic oxidation of aluminum |

Introduction to anodic oxidation of aluminum: | The anodic oxidation of aluminum or aluminum alloy is called the anodic oxidation of aluminum and aluminum alloy. |

Product usage: | After anodized on the surface, the corrosion resistance, hardness, wear resistance, insulation and heat resistance of aluminum or aluminum alloy products are greatly improved.Therefore, anodic oxidation technology has been widely used in the construction industry, aviation and aerospace industry, electrical and electronic industry, food industry, chemical and pharmaceutical industry, transportation and other fields. |

Process flow: | Oil removal → alkali washing → acid washing → polishing → anodic oxidation → washing → coloring → sealing → drying |

Our strengths | |

1. Till 2019, we have been engaged in the field of etching for 20 years. In 2015, the company invested in building a new industrial park in nantong. | |

2. The group company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the group company has passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained multiple property rights and patents.Zolida has been focusing on technology research and development, with laboratories and external employment and training of high-tech talents, is a benchmark enterprise in the industry. | |

3. As a member of PCMI, the world etching association, the company can share information and equipment of the global etching industry. | |

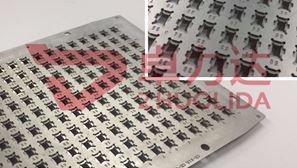

4. Several anodic oxidation production lines have been introduced, and the company has an automatic adding system and regeneration system for potions. While developing, the company also pays attention to environmental protection.The company aspires to become an environmental protection enterprise, green enterprise. | |

5. Many metals need anodic oxidation after etching, which can help improve the precision, finish and aesthetics of parts and other products. | |

6. Shenzhen zhuolida, kunshan zhuolida and nantong zhuolida three production bases, with a comprehensive area of more than 40,000 square meters.Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions.The first floor of building 1, zhuolida, nantong is the electrophoresis workshop.The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the requirements of production capacity and precision of various products.The fourth floor is the vacuum diffusion welding workshop.Building 2 is an electroplating industry. | |

01

Anodic oxidation of aluminum:

With the rapid development of aluminum processing industry, aluminum surface treatment has become an essential part of aluminum processing.Aluminum products after surface treatment, greatly improved wear resistance, corrosion resistance, light resistance, weather resistance and other properties, more can be on a variety of beautiful bright colors.To meet the requirements of the aesthetic sense of The Times, so the application value of aluminum is much higher.

02

How is the voltage controlled during anodic oxidation of aluminum?

The voltage is regulated according to the temperature of the solution.When the solution temperature is low, the voltage at the upper limit shall be adopted, because the oxidation film obtained at the lower solution temperature is dense and the oxidation film resistance is large. To thicken the oxide film, a higher voltage must be adopted, otherwise it is difficult to obtain the normal quality of the oxide film.When the temperature of the solution is high, the voltage should be lowered, otherwise the film solution will be too fast due to the resulting loose oxide film, and it is difficult to obtain the ideal oxide film thickness.

03

Anodic oxidation of aluminum is generally carried out in an acid electrolyte with aluminum as the anode.In the process of electrolysis, the anion of oxygen interacts with aluminum to produce oxide film.This film is not dense enough at the beginning of formation. Although there is a certain resistance, the negative oxygen ions in the electrolyte can still reach the surface of the aluminum and continue to form the oxide film.As the film thickness increases, the resistance increases and the electrolytic current decreases.At this point, the outer oxide film in contact with the electrolyte chemically dissolves.

04

When the rate of oxide formation on the aluminum surface gradually balances with the rate of chemical dissolution, the oxide film can reach a greater thickness under this electrolytic parameter.Aluminum anodized film porous outer layer, easy to absorb dyes and colored substances, so can be dyed, improve its decorative.The corrosion resistance and wear resistance of the oxide film can be further improved by sealing with hot water, high temperature steam or nickel salt.

If you want to find a factory for aluminum anodizing, please contact us. All staff of zolida will serve you wholeheartedly.