Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

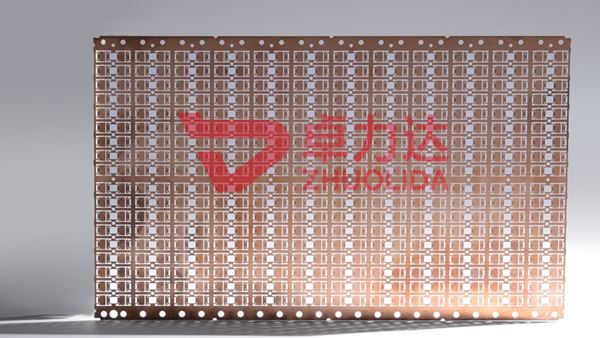

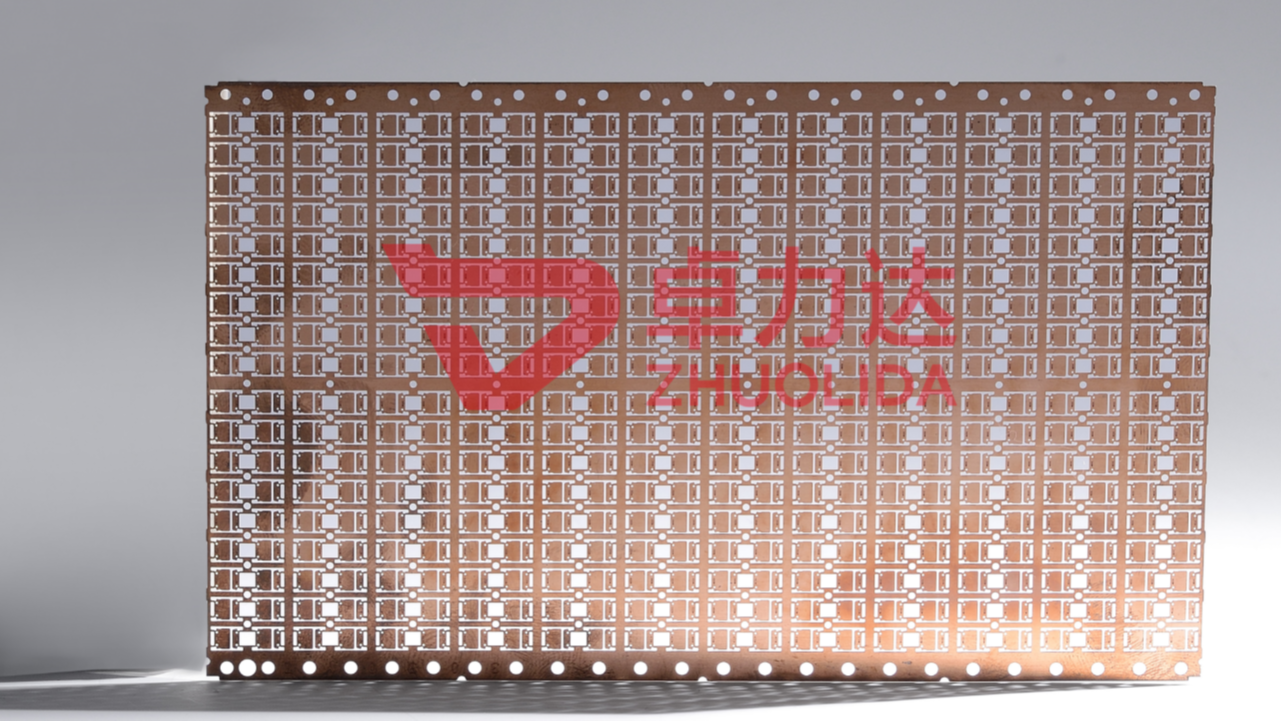

With the maturity of LED lighting application, the demand for medium power LED is growing rapidly. In recent years, LED packaging plant has been actively importing EMC supports suitable for medium and high power. EMC and SMC packaging has become the future trend.

02

EMC bracket has the advantages of high heat resistance, high current, high power, high density, UV resistance, small volume, suitable for mass production and application.

03

EMC supports have excellent mechanical, bonding and corrosion resistance, low curing shrinkage and thermal expansion coefficient, and good dimensional stability. The characteristics of good technology and good comprehensive performance, it is bound to shine in the field of LED packaging.

04

EMC has incomparable advantages in some specific fields such as ceramics and PPA, and the future development trend of the industry is promising.

Our company's EMC support is blanking without cutting, which is produced by chemical etching process. Chemical etching process can achieve the half-etching effect of EMC support and can be controlled, with better precision and higher precision, and no need to invest in huge production equipment. With the existing production line, it can be mass produced to improve production efficiency. If you want to find an EMC support manufacturer, please contact zolida, we provide free EMC support technology solutions and etching industry information. All staff of zolida company will serve you wholeheartedly.