Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product introduction | |

Product introduction | Seamless welding |

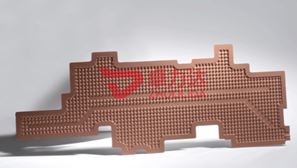

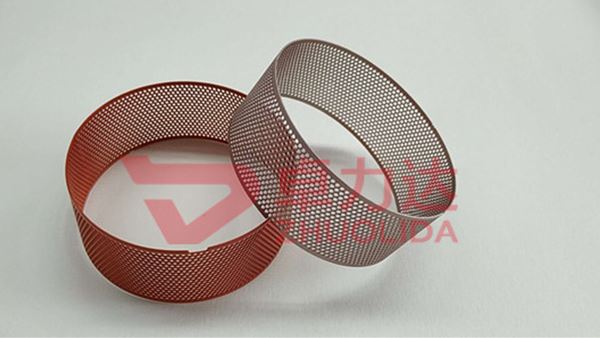

Welding principle | Seamless welding is a fusion welding using arc as heat source and gas as protective medium.Arc, molten pool, and high temperature state of the base metal are placed in the protective gas, the welding area to protect the appearance of nearly seamless state. |

Product use | Seamless welding plays a key role in different industries, helping parts and other products to improve the precision and finish, product aesthetics, and can effectively shorten the overall mold production and processing cycle. |

Product after-sale | The quadratic element, the imaging instrument precision detection, the 24-hour service hotline 0513-81601666. Responsible for all the products of our company.Whether it is service attitude, or product quality, early communication about product design, sales quality of service, can be directly communicated.Our factory has a quality control team, a quick response mechanism, for customer complaints, within 24 hours to reply.Propose corrective measures within 48 hours and complete finished products delivery within three days. |

Our strengths | |

1. Till 2019, we have been engaged in the field of etching for 20 years. In 2015, the company invested in the construction of a new industrial park in nantong. | |

2. The company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the company has passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained multiple property rights and patents.Zolida has been focusing on technology research and development, with a professional laboratory and external employment and training of high-tech talents, is a benchmark enterprise in the industry. | |

| 3. As a member of PCMI, the world etching association, the company can share information and equipment of the global etching industry. | |

| 4, the introduction of a number of etching production lines and seamless welding equipment, has a potion automatic addition system and regeneration system, the company's development also pay attention to environmental protection, self-built large sewage treatment system, waste water reuse rate of more than 40%, is a rare in the metal etching industry to build a dedicated waterless treatment system of the manufacturer.The company aspires to become an environmental protection enterprise, green enterprise. | |

| 5. Nantong zhuolida integrates etching and seamless welding to strive for survival, development and benefit with high precision and standard. | |

6. Shenzhen zhulida, kunshan zhuolida and nantong zhulida three production bases, with a comprehensive area of more than 40,000 square meters.Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions.The first floor of building 1, zhuolida, nantong is the electrophoresis workshop.The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the requirements of production capacity and precision of various products.The fourth floor is the vacuum diffusion welding workshop.Building 2 is an electroplating industry. | |

01

The so-called seamless refers to the protection level of the welding area during the welding process.Generally we say arc welding, its arc is exposed to air, seamless welding generally USES inert gas as a protective layer, it will be the arc, molten pool, and high temperature state of the base material are placed in the protective gas, so called seamless welding.In this sense, its development prospects are certainly better than conventional conventional arc welding, and with the development of protection methods, the future of seamless welding will be more extensive.

02

Seamless welding technology. The welding device converts the current 50/60hz electrical frequency into 20KHz or 40KHz electrical energy through a transistor functional device.The welding head is an acoustic device that transmits the mechanical vibration energy directly to the pressing product.The vibration is transmitted to the bonding surface by the welding work piece and the vibration friction produces heat to melt the plastic, but the welding strength is close to that of the bonded material.

03

Seamless welding technology, also improve the precision of the parts, finish and appearance of the impressive.At the same time, seamless welding technology implements high energy efficiency control in the process of injection molding and shortens the machining cycle of the mold.

If you want to find a seamless welding factory, please contact us, zhuolida staff will be dedicated to serve you.