News

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

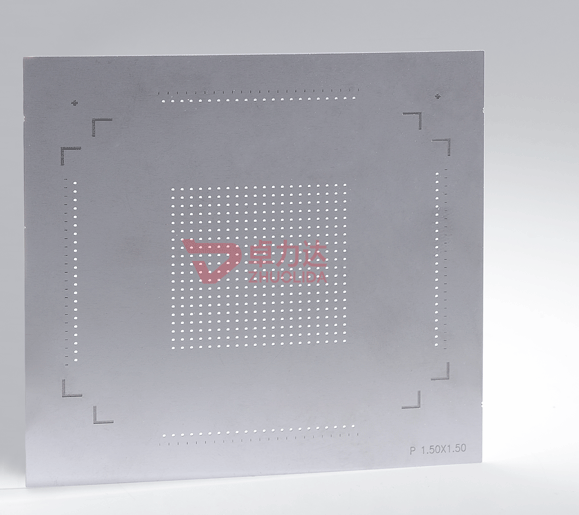

The standard screen plate is a metal sheet with a round hole, the wall of the round hole is at right Angle to the front end of the screen, and the hole plate axis is concentric with the pipe axis when installed.So what effect does the shape of the screen plate etch have on the screen?

The shape of screen hole directly affects the effective area of the screen, which refers to the ratio of the area occupied by the pure screen hole of the screen to the geometric area of the screen surface, also known as the effective screen surface.The larger the effective area of the sieve, the greater the number of sieve holes per unit screen surface, the greater the probability of material passing through the sieve holes, so the higher the production capacity and screening efficiency.

In the practice of sifting, the commonly adopted mesh shapes are round, square and rectangular.The screen hole of punching screen surface is mostly round, while braided screen surface has oblong hole and square hole.It has been proved by practice that the effective screen area and the chance of ore particles passing through the screen are different with different screen shapes.The effective area of rectangular sifter is larger, followed by square sifter, and the effective area of circular sifter is smaller. Therefore, the productivity of unit sifter decreases in the order mentioned above.Another advantage of the rectangular screen hole is not easy to block the screen hole, because the ore through the screen: only three or two sides of the screen hole contact, resistance is small.However, its disadvantage is that it is easy to make the long strip and flake ore particles through the sieve hole j, so that the product size is not uniform.

Screen plate main materials: 304, 304L, 316, 316L stainless steel punching mesh, stainless steel woven mesh, stainless steel welding mesh.

Properties: acid, alkali, high temperature, tensile and wear resistance.

USES: for acid and alkali environment screening and filtration, oil industry for mud screen, chemical fiber industry for screen screen, electroplating industry for pickling screen.

Type: single layer, multi-layer;It can be divided into round shape, rectangle shape, waist shape and oval shape.There are two layers and three layers.

This product mainly USES the screen plate filter screen piece according to the process:

1, multilayer spot welding filter.

2, multilayer edge filter screen.

Stainless steel filter screen by shape: rectangular, circular, circular, distance shape, waist shape, shaped.

According to the structure: single-layer screen, multi-layer composite screen, combined screen.

According to the number of layers: single, double, three, four, five, multi-layer.

The screen plate etching products produced by zolida can ensure the extremely high precision, the precision can reach +/-0.01mm, and the processing quality is stable, the batch is clear, the quality control system is strict.Screen plate etching can meet the need of precise assembly of different parts and improve the quality and precision of the whole product.With the service concept of precision, timeliness, convenience and environmental protection, the company has fast manufacturing, quick distribution system and emergency service team to serve every new and old customer.