News

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

Etching processing is to need etching metal parts to immerse in the etching solution is composed of various kinds of chemical composition, at room temperature or heating cases, after a certain time of reaction, need to slowly dissolve etching of metal, meet the need of etching depth, the metal surface shows a three-dimensional sense of concave and convex decorative words or patterns.

The process of etching is actually the self-dissolution of metal in a chemical solution, that is, the corrosion process.This process of dissolution can be carried out by chemical or electrochemical mechanisms, but since the solution of metal etching is a general solution of acid, base and electrolyte.Therefore, the chemical etching of metal should be carried out according to the electrochemical dissolution mechanism.

After the removal of the protective film of the etched workpiece, it will show the luster of the metal, is corroded to the matte or matte, the layer is clear, after the bleaching passivation, the surface cover on the protective paint, that is the finished product.There are also in the corrosion to the concave filled with a variety of color paint, the formation of color patterns covered with protective paint.Process after the pint film is often electroplating, plating alloy or gold or silver, and then paint or directly.There are also local electroplating, for example: do not remove the protective film, the corrosion of the parts of the plating other colors, and then remove the protective film, so that the gold and silver bicolor products.It is exquisite and gorgeous.Cover light with protective paint before someone USES from dry paint, at that time good-looking but not durable, now multi-purpose drying coating, violet light (UV) curing coating or electrophoretic coating.Stainless steel parts used in industrial products, usually remove protective film, clean good, of course, there are special requirements may also need surface coloring, passivation or coating.

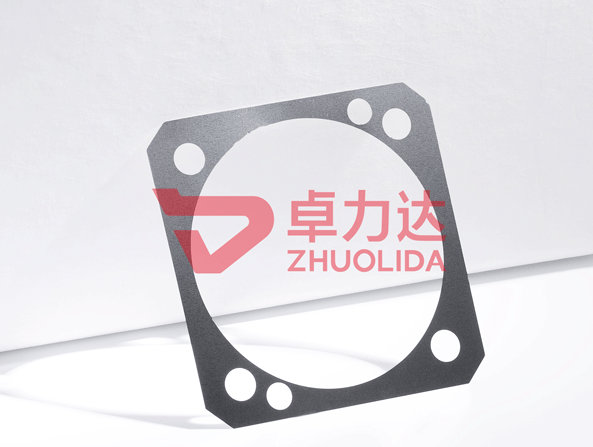

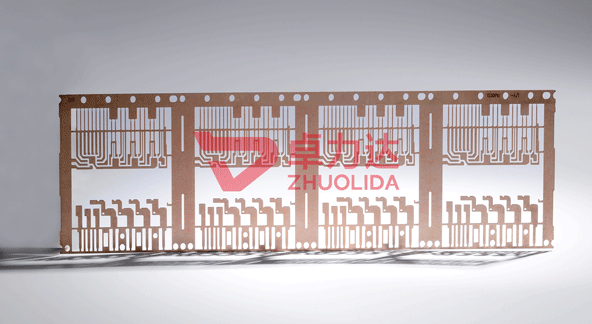

Etched material

Etched materials can be divided into metallic materials and non-metallic materials, here we refer to the processing, is specially for the metal materials etched processing, different metal materials need to match special potions.Zolida is mainly produced by etching stainless steel, copper, copper alloy, and other special rare metal materials like molybdenum can also be processed.Zolida is a strong precision etching brand, with a number of imported etching production lines, and a number of the world's top 500 enterprises to provide free metal etching process solutions, 24-hour service.

Zolida is a high-tech enterprise engaged in precision metal etching processing, SMT laser template development and production, vacuum diffusion welding, products through ISO, quality environmental management system certification, superb technology, intimate after-sales service, has been widely recognized by a large number of customers.Enquiry hotline for etching processing: 0513-81601668 182-0629-3159