News

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

With the continuous innovation and development of communication technology, it is inevitable that 5G mobile phone will become the main trend in the future.As 5G phones are more versatile and intelligent, the integration of chips, the core components of the phone, is higher, which will inevitably lead to the increase of power consumption of 5G phones compared with 4G phones.Therefore, the 5G era has put forward higher requirements and challenges for the mobile phone heat dissipation processing technology and the heat dissipation material upgrade on the previous basis.Cooling problem is still the industry to seek breakthroughs in the difficulties.

In fact, in recent years, from graphite cooling to heat pipe cooling, and now the temperature plate cooling and so on, mobile phone cooling technology has been constantly updated.According to the insiders in the industry, the chip power of 4G is 1w-2w, and the graphite material with high thermal conductivity is enough to solve the problems of local overheating and space limitation.The maximum power of 5G chips will be 5w-7w.With the increase of chip power consumption and the change of cell phone structure (folding screen), high thermal conductivity graphite material has been difficult to meet the needs of mobile phone cooling.

Among various cooling schemes for 5G mobile phones at present, the uniform temperature plate, as a new way to solve the problem of mobile phone cooling, has gradually become the main demand and industry outlet in the 5G era with its unique cooling effect.In 5G flagship phones released earlier this month, huawei's Mate 20 X and samsung's Galaxy S10 cooling systems both use an equal-temperature plate.

Reading this, many people may ask, what is the temperature plate?What are the advantages of a uniform plate?Next small make up the temperature plate and the traditional heat pipe for comparison, to answer the above questions.

Uniform temperature plate in English written Vapor Chambers, so referred to as VC, in the industry is also commonly called uniform temperature plate, uniform heat plate, plane heat pipe or cooling plate.With the continuous improvement of chip power and density in recent years, VC equal-temperature plate, as a heat transfer element, has been widely used in the cooling of laptop, network server, 5G mobile phone and other high-power devices.

Heat pipes are ideal for connecting heat sources to distal fins or substrates, especially for relatively complex and curved heat transfer paths.Even if it is a straight path, the heat pipe, not the VC equalizer, is suitable in cases where heat transfer is required at the far end.This is the key difference between heat pipe and VC heat dissipation plate, the focus of heat pipe is to transfer heat.Although the cooling function of the two is the same, the methods and ways of realization are different.Although the VC cooling plate can be considered as a plane heat pipe, it obviously has more core advantages than the traditional heat pipe.Since the use of the VC board allows direct contact between the heat source and the cooling equipment, the thermal resistance can be reduced quickly and efficiently.Secondly, the shape of the VC equalizing plate is planar, which can make the surface temperature distribution more uniform, so the equalizing effect is better than that of metal and traditional heat pipes.

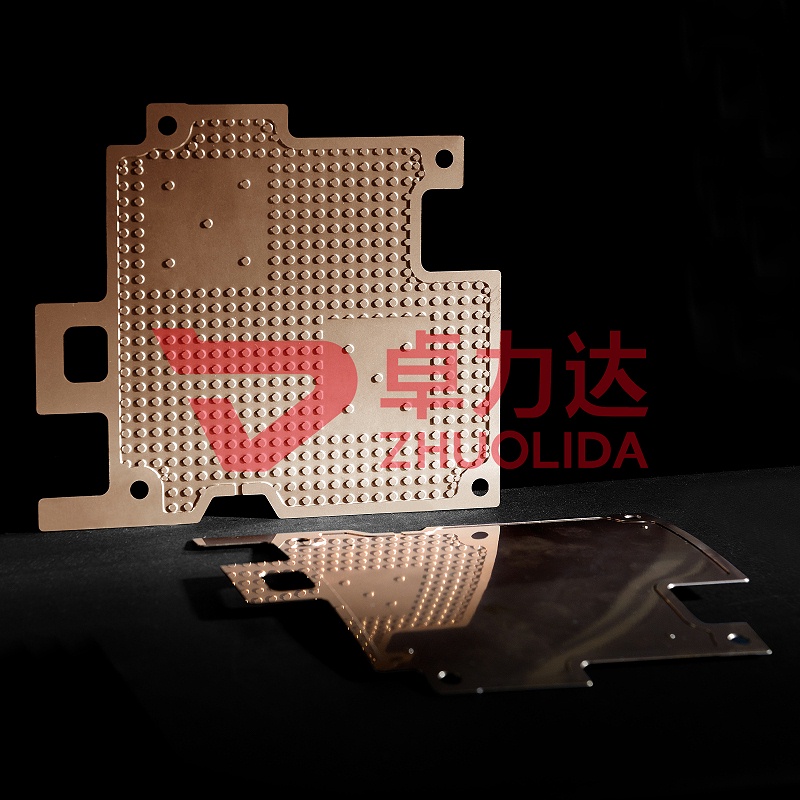

At present, the main domestic use of the etching process to produce soaking plate.The vacuum cavity was etched on two thin copper alloys, and the capillary copper mesh was welded into the cavity. Then the upper and lower two pieces were heated at high temperature to micro-melt state and sintered together by pressure. Finally, the vacuum was removed and the coolant was injected.VC equal-temperature plate etching technology has obvious advantages over other traditional production methods in product thinness and cavity structure forming.

As one of the few VC board etching manufacturers in China, nantong zhuolida board line has been officially used for mass production of VC board products.After previous market analysis and research, equipment procurement and a series of preparatory work, the company specially set up this year ZhuoLiDa temperature plate division, to introduce advanced production equipment set up VC plate etching production line are temperature, recruitment has years of experience of mean temperature plate corrosion technical personnel team, layout of cooling plate etching of VC market at home and abroad, especially in the east of China.Nantong ZhuoLiDa as a mature technology of mean temperature board supplier, with years of accumulation of metal etching technology, combined with the mean temperature of high-end equipment, plate corrosion temperature plate etching in experienced technical personnel, for various industries provide detailed professional consulting, production and after sales in the integration of VC soaking plate etching solution as a whole.