Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

Influence the properties of weld and the process parameters are: welding time and temperature and pressure when other parameters are fixed, the kinds of protective gas with high pressure can produce better joint limit depends on the overall deformation of the weldment limit equipment tonnage for dissimilar metal diffusion welding, using pressure to reduce or prevent larger diffusion holes have a role in addition to the static pressure diffusion welding heat diffusion welding pressure usually choose between 0.5 ~ 50 mpa

02

Diffusion time refers to the welding in the welding temperature time on the welding time guarantee the diffusion process is complete, in order to achieve the required strength of the diffusion time is too short, the joint strength can not meet the stability and the strength of the parent metal is equal but too high temperature and high pressure duration, cannot afford any further improve the quality of joint function, using some sort of welding parameters, welding time several minutes enough purity of welding protective gas flow pressure or vacuum leak rate will affect the quality of diffusion welding head is commonly used protective gas argon gas, can also be used for some materials high purity nitrogen hydrogen and helium gas

03

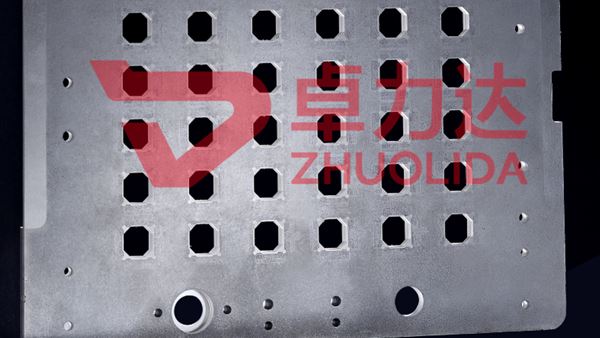

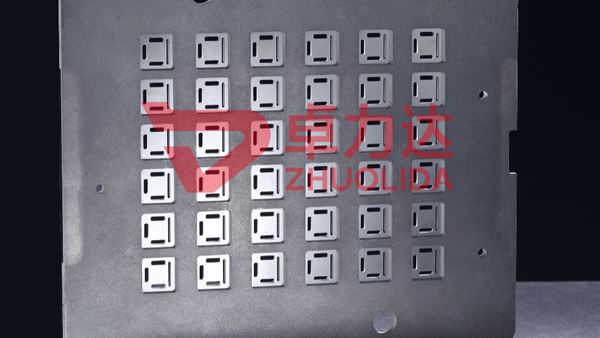

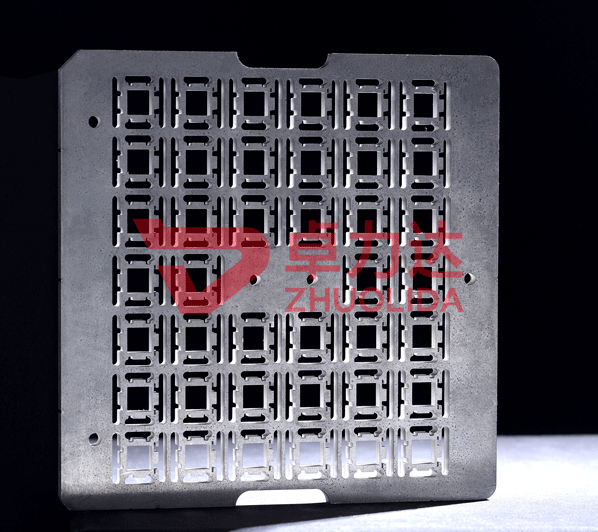

Diffusion welding can be used to weld the joints with large section, and the workpiece with complicated structure, which is not easy to be approached and has a large thickness difference

04

Diffusion welding is to form a welding joint under the condition that the metal does not melt, which makes the contact distance between the two surfaces to be welded reach within 1 m, so that the interatomic gravity can act and form a metal bond to obtain a certain strength of the joint

ZhuoLiDa shenzhen ZhuoLiDa kunshan ZhuoLiDa nantong ZhuoLiDa three production bases, including nantong ZhuoLiDa with nanjing university of aeronautics and astronautics, and Harbin industrial university is a vacuum diffusion welding technology and vacuum diffusion welding equipment r &d and manufacturing, set up a joint laboratory, common to do scientific research and technology research and development, now our precision etching products with vacuum diffusion welding technology is widely service military-industrial complex medical precision filter mould nuclear power automation and so on semiconductor equipment manufacturing industry we can provide free diffusion welding processing solutions as well as about true diffusion welding industry information service