Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

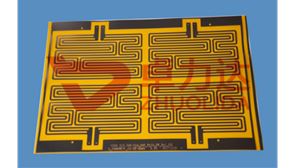

Even if the wide heat exchanger plate, the fluid can be fully evenly distributed in each corner of the plate, so that the pressure loss in the diverging area is small.Plate of all involved in heat transfer, heat transfer area of plate of all physical area into effective heat transfer area, there is no heat transfer dead zone, flow there is no dead Angle, not prone to fouling, not easy to appear fouling caused by chloride ion corrosion, can make full use of the allowable pressure drop, increase the convective heat transfer part of the flow rate, improve the overall thermal efficiency.

02

Micro-channel heat exchanger is a new type of heat exchanger. Compared with the traditional heat exchanger, the flow, evaporation and heat exchange mechanism are changed due to the decrease of the flow channel size of internal heat exchanger plate, which brings a series of advantages to the product, such as low material cost, small volume, light weight and high conversion efficiency.The introduction of microchannel technology makes it possible to miniaturize highly integrated electronic equipment cooling and related cooling systems.

Our company is based on the test data have mastered and thermal fluid analysis software, for the customer to carry out the design of the micro heat exchanger plate and the research and development work, combined with our experiences in related products manufacturing technology advantage, can accomplish the production in a relatively short time, depends on the heat transfer test platform independent research and development, and actual working condition of simulation testing finished products, providing customers with complete and reliable heat exchanger plate solution.If you want to find a heat exchanger plate etching manufacturers, please contact us zhuolida, zhuolida staff will be dedicated to serve you!